Conical Hoppers

Homer City Automation’s Conical Bulk Hopper Feeder was designed using proper mass flow principles. This conical hopper will promote first-in, first-out of bulk materials. The optimized valley angles of the conical hopper will eliminate bridging as well as rat holing.

The valley angles will eliminate material buildup when problematic materials are handled. Best of all, the design of this conical hopper allows for cost-effective fabrication and can easily conform to FDA specifications, which results in an improved price alternative to conventional spun hoppers.

Homer City Automation’s standard Conical Hopper has a one cubic foot storage capacity with a 3” wide flat bottom vibratory trough. A variety of bin capacities and trough widths can be offered to meet specific customer requirements.

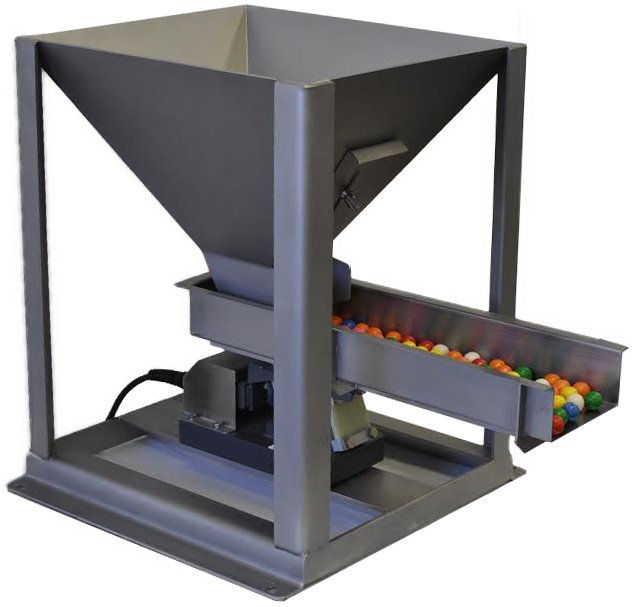

Rectangular Hoppers

The Rectangular Hopper was designed to feed most dry bulk materials for feeding, blending and packaging applications. The Rectangular Hopper bin, trough and frame are constructed of Type 304 stainless steel, and can easily conform to FDA type specifications. An adjustable gate between the bin and trough is provided to regulate material depth. A vibratory trough is incorporated for volumetric conveying of material.

Homer City Automation’s standard Rectangular Hopper has a one cubic foot storage capacity with a 6” wide flat bottom vibratory trough. A variety of bin capacities and trough widths can be offered to meet specific customer requirements.